Purpose:

The purpose is: drilling of exploratory & field wells; carrying out well overhaul, including kickoff of second bore in running well; other type of well construction works.

Design features and advantages:

Design features and advantages:

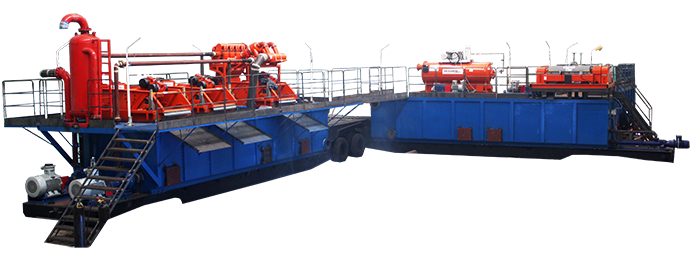

The drilling rig consists of separate blocks mounted on semi-trailers which are transported by universal tractors, that provide mobility and shorten the time of well to wel transportation;

Fault-free operation source is provided by Caterpillar C-15, C-18 power engines, Allison HD 47000FS transmission and “WPT" drives engaging pneumatic clutches;

The rig hydrosystem drive is arranged from the supplementary power take-off, which allows to perform mounting and dismounting at the well without connecting electric power and relieve the drive when doing roundtrip operations;

Fastening of the mast guy wires is arranged on the rotary base cross beam brackets, which does not require anchors and enhances mobility;

Load guy lines are equipped with force dynamometers;

Availability of two pneumatic lines (the main goes from lifter compressor, the auxuliary goes from compressors block) provides their backup and air supply increase if necessary;

Parameters of mud pumps operation can be adjusted from the driller’s platform;

Extension of the derrick upper section is performed by the drawworks, both from the main and from the emergency drive;

The rotary brake is operated pneumatically from the driller’s control;

The original system of split-type elements connection by means of special pins without threaded joints allows to shorten the time required for mounting and dismounting of the blocks;

There is a multimodule power block, which contains:

transformer module;

complex operation parameters control module;

module of diesel generator and compressors block;

The drilling parameters control system with an archiving capability allows controlling the accuracy of drilling activities and roundtrip operations;

There is a possibility to output the drilling parameters data to the drill operator’s computer in real-time mode and their record, besides, there is a nonvolatile block recording the basic parameters (pressure in the supply manifold and weight on hook).

The drilling complex comply with the requirements of «The safety rules in the oil and gas industry of the Republic of Kazakhstan» and the requirements of «The safety rules in the oil and gas industry of the Russian Federation» PB 08-624-03.

Technical Specifications

Lifting rig

| Nominal load on hook kN, (t) | 1250 (125) |

| Mounting base | self-propelled off-road platform |

| Diesel engine Caterpillar with a spark arrester (kW) | 448 |

| Nominal drilling depth, m (drill pipes, weighing 30 kg/m) | 2500 |

| Hook lifting speed, m/s from the basic drive | 0..1,59 |

| Drill-pipe stand length, m | 18-20 |

| Derrick - two-sectional, telescopic with open front face | |

| Height of derrick from the ground, m | 36 |

Rotary base

| Drilling floor mark height from the ground, m | 5,2 |

| Base block for working drilling floor, dimensions, m | 5 х 5 х 5 |

| Distance from earth to rotary support beams that provides for free installation of preventer block, m |

4,06 |

Pump unit - 2 pcs

| Drilling pump | three piston | ||

| Number of main drilling pumps, pcs. | 1 (1 or 2-on customer’s demand) | ||

| Power of drilling pump, kW | from 235 up to 735 | ||

| Ultimate pump pressure (maximum), h/p | from 30 up to 41 | ||

| Drive type | from diesel or electric drive | ||

Circulation system

| Circulation system | Block-module type |

| Total payload volume of circulating system reservoirs,m3 | 120 |

| Steel tanks for drilling agent as set | 3 |

| Drilling agent mixer: mechanical/hydraulic | 6/8 |

| Shaker | 2 |

| Desander | 1 |

| Cyclone separator | 1 |

| Degasifier (vacuum) | 1 |

| Sludge pump | 4 |

| Semi-trailer | 3 |

| Topping-up capacity, m3 | 3 |

| Technological block | 1 |

| Capacity, m3 | 40 |

| Sludge pump | 1 |

Energetic system of complex

| Diesel, power station, power 400 kW | 1 |

| Substation 380 Volt connected to the industrial network 10 kW | 1 |

| Control and communication equipment |